pH, Redox, Leifähigkeit und Sauerstoff – für diese Parameter sind Memosens-Sensoren verfügbar. Und das Besondere an Memosens? Die Messsignale werden digitalisiert und induktiv, also kontaktlos, übertragen. So einfach werden Zuverlässigkeit und Verfügbarkeit der Messstelle entscheidend verbessert. Memosens hat eine perfekte galvanische Trennung, ist absolut wasserdicht und resistent gegen Umgebungseinflüsse. Da sehen andere Sensoren ganz schön alt aus. Memosens – der sichere Industriestandard.

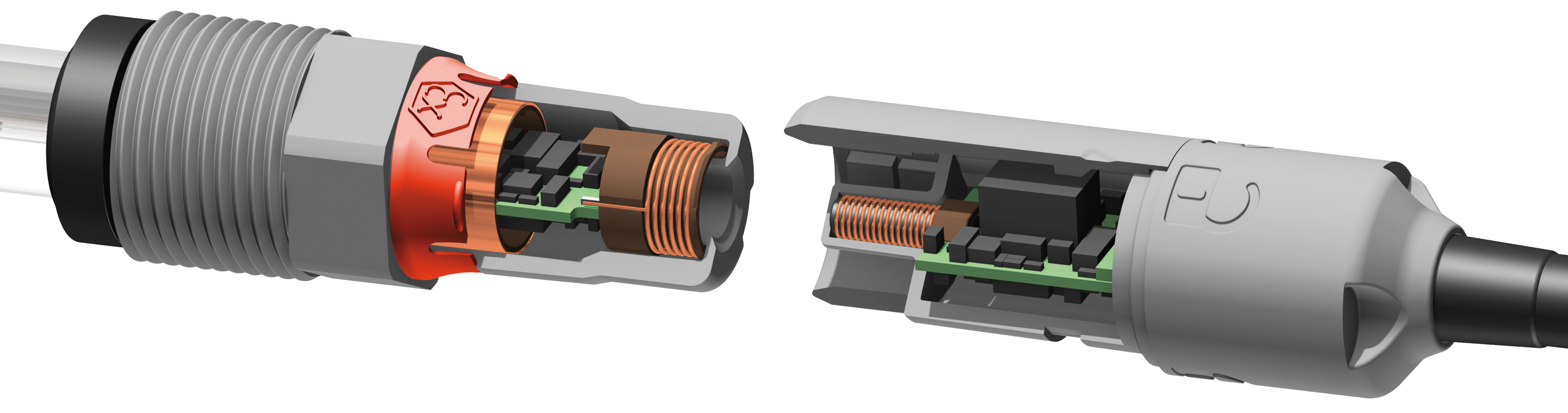

Sehr hohe Anforderungen werden von der Flüssigkeitsanalyse an den Sensor und an die Übertragung des Messwerts vom Sensor zum Messumformer gestellt. Bei der pH-Messung erfordern zusätzlich niedrige Messsignale und sehr hohe Innenwiderstände der Sensoren eine hochohmige Anbindung an den Messumformer. Daher führte bei herkömmlichen, analogen Stecksystemen mit Kontakten Feuchtigkeit zur Veränderung des Messwertes bis hin zum kompletten Ausfall der Messung. Für Memosens-Sensoren ist das kein Thema mehr. Vergessen Sie´s. Die Memosens-Technologie revolutioniert die Sicherheit der Messung, indem sie den Messwert im Sensor digitalisiert und kontaktlos zum Messumformer transferiert. Bekannte Probleme, verursacht durch herkömmliche Stecksysteme, gehören der Vergangenheit an. Der Technologiesprung mit Memosens hat zu einer neuen Generation von Sensoren geführt und die prinzipiellen Einschränkungen bisheriger Technologien eliminiert.

Die mechanisch sichere und kontaktlose Verbindung zwischen Sensor und Kabel macht eine sichere Funktion sogar unter Wasser möglich. Weil alle sensorrelevanten Daten direkt im Sensorkopf gespeichert werden, ist eine vorausschauende Wartung möglich. Nachweislich können dadurch Wartungskosten deutlich reduziert und die Standzeiten der Sensoren verlängert werden. Gleichzeitig werden sowohl die Prozesssicherheit erhöht als auch Anlagenstillstände minimiert. Und als wäre das noch nicht genug, spart Memosens bares Geld bei den Investitionskosten.

Kontaktlose, digitale Messwertübertragung

EMV-Sicherheit garantiert

Einfach im Labor kalibrieren

Datenmanagement vom Feinsten

Nie mehr falsche Messwerte

Datenspeicher inklusive

Die innovativen Memosens-Systeme bieten die ideale Lösung für Sicherheit und Bedienkomfort in der Analysenmesstechnik. Mit allen gängigen Feldbussen sind Memosens-Systeme natürlich offen für alle Prozessleit- und Asset-Management-Systeme. Dabei haben Anwender die Möglichkeit, Memosens-kompatible Komponenten voneinander unabhängig agierenden Anbietern zu beziehen und frei miteinander zu kombinieren. Und mit über einer Million Memosens-Sensoren, und es werden täglich mehr, spricht man bereits von einem De-facto-Standard in der Prozessanalytik, den wir stetig weiter entwickeln.

Für Anwender bringt Memosens eine Menge an Vorteilen mit sich. Kein Wunder also, dass sich auch andere Hersteller von Analysenmesstechnik für die Nutzung der Memosens-Technologie interessieren. Kein Problem. Gerne geben wir Ihnen weitere Informationen über Kooperationen und Lizenzen. Wir freuen uns auf Sie.