pH, ORP, conductivity and oxygen – Memosens sensors are available for these parameters. What's special about Memosens? The measuring signals are digitalized and transferred inductively i.e. via a non-contact connection. That's how easy it is to cause a radical improvement in measuring point reliability and availability. Memosens features complete galvanic isolation and is fully waterproof and resistant to environmental influences. Other sensors seem pretty old by comparison. Memosens – the safe industry standard.

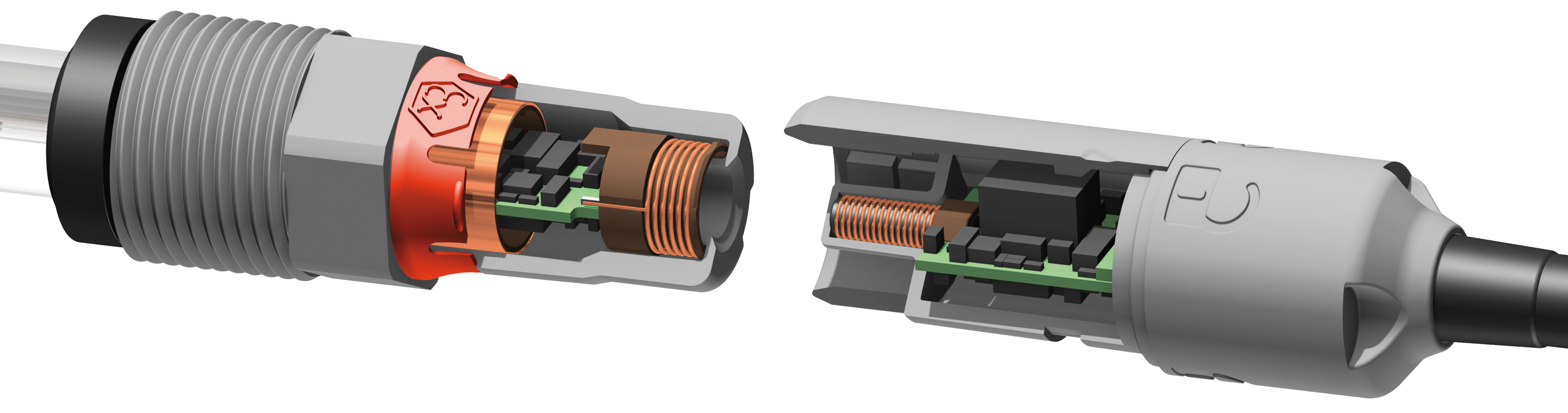

Liquid analysis places massive demands on the sensor and on the transmission of the measured value from the sensor to the transmitter. In addition, when it comes to pH measurement, low measuring signals and very high sensor internal resistances require a high-impedance connection to the transmitter. That is why the presence of moisture in conventional, analog connector systems with contacts resulted in the measured value being altered or even caused the complete failure of the measurement.

For Memosens sensors, this is no longer an issue. Put it out of your mind. Memosens technology is revolutionizing measurement safety by digitalizing the measured value in the sensor and sending it to the transmitter via a non-contact connection. Familiar problems caused by conventional connector systems are now a thing of the past. Memosens represents a technological leap resulting in a new generation of sensors. It boasts additional benefits while also eliminating the basic limitations of previous technologies.

The mechanically safe, non-contact connection between the sensor and the cable enables the technology to function safely, even under water. As all sensor-related data are stored directly in the sensor head, it is possible to perform predictive maintenance. This has been proven to reduce maintenance costs significantly and to increase sensor operating time. At the same time, process safety is increased and system downtime reduced to a minimum. And as if that wasn't enough, Memosens saves hard cash when it comes to capital costs.

Non-contact, digital measured value transmission

EMC safety guaranteed

Easy calibration in a laboratory

Top-quality data management

No more incorrect measured values

Memory included

The innovative Memosens systems provide the ideal solution for safety and ease of use in analytical measurement technology. Teamed with all widely used fieldbuses, Memosens systems are of course open for all process control and asset management systems. Users have the option of purchasing Memosens-compatible components from independently acting providers and of combining them in whatever way they want. And with over a million Memosens sensors in operation (a number that is growing daily), the word is that they have already become a de facto standard in process analysis, and one which we are continuing to develop.

Memosens has many benefits to offer the user. It is therefore no wonder that other manufacturers of analytical measurement technology are interested in using Memosens technology. No problem. We are happy to provide you with further information on our cooperation and licensing agreements. We look forward to hearing from you.